Plastic waste is one of the most pressing environmental issues of our time. But what if plastic could have a second life not as pollution, but as purpose-driven products that last for decades?

At Resourceful Living, that’s exactly what we do. We take everyday plastic waste and transform it into long-lasting, beautiful, and functional materials used across construction, landscaping, and design.

This article explores how we recover, repurpose, and reimagine plastic helping drive Australia’s transition to a circular economy.

📌 Related: How Recycled Plastic Products Drive the Circular Economy in Australia

✅ Explore products made from recycled plastic

The Problem: Plastic Waste in Australia

Australia produces over 2.5 million tonnes of plastic waste each year with less than 13% recycled.

Sources include:

- Packaging and containers

- Household goods

- Industrial offcuts and manufacturing waste

This plastic often ends up in:

- Landfills

- Incinerators

- Oceans and waterways

📎 Related: Plastic Pollution in Australia: How the Building Industry Can Help

✅ Join the movement to reduce plastic waste

How We Source Recycled Plastic

We partner with:

- Local councils and community programs

- Industrial and commercial waste generators

- Domestic recycling collection facilities

Common materials include:

- HDPE (milk bottles, shampoo bottles, buckets)

- PP (lunch containers, caps)

📎 Related: What Happens to Recycled Plastic? Behind the Scenes of Our Process

The Process: Turning Waste into Worth

1. Sorting & Cleaning

Contaminants, labels, and residue are removed to prepare plastic for remanufacture.

2. Shredding into Flakes

Clean plastic is turned into high-quality, uniform flakes.

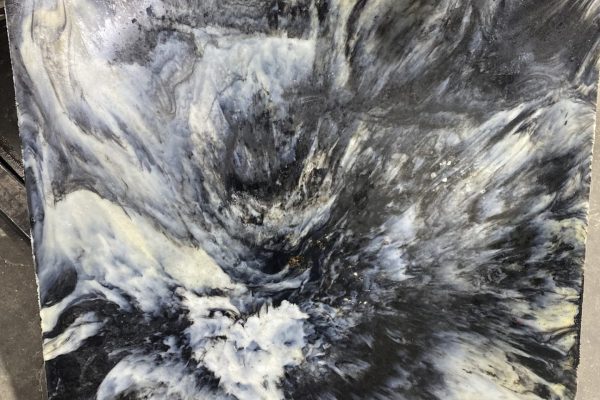

3. Melting & Compression Moulding

Flakes are melted and compressed into high-performance sheets and panels.

📌 Related: The Lifecycle of a Recycled Plastic Panel

What We Create: Durable Recycled Products

Our plastic panels and sheets are used in:

- Commercial interiors

- Landscaping and public space infrastructure

- Outdoor furniture

- Educational and community projects

Properties include:

- UV- and moisture-resistant

- Structurally strong

- Splinter-free and safe

📎 Case studies: Recycled Plastic in Commercial Fit-Outs: Real-World Case Studies

Why Recycled Plastic Products Matter

- ♻️ Divert plastic from landfill

- 🌿 Replace virgin materials

- 🔁 Enable circular construction

- 👣 Reduce project carbon footprints

📎 Related: Government Incentives for Using Recycled Materials in Construction

✅ Book a consult for your project

Design & Compliance Benefits

Our panels made from recycled plastic help projects:

- Achieve Green Star and NABERS targets

- Meet ESG and sustainability frameworks

- Stand out with a visible sustainability story

📎 Related: Why Designers Love Working with Recycled Plastic Panels

✅ Request compliance documentation

How It Compares to Traditional Materials

| Feature | Virgin Plastic | Timber | Recycled Plastic Products |

|---|---|---|---|

| Environmental Impact | High | Medium | Low |

| Maintenance | Low | High | Low |

| Aesthetic Options | Limited | Natural | Custom colours & flecks |

| Lifespan | Variable | 5–15 years | 20–50+ years |

Scaling the Impact: More Than Just Panels

We’re expanding our recycled plastic product range to include:

- Wall cladding and signage

- Decorative panels for design

- Modular furniture components

- Infrastructure for public spaces

We also offer take-back and recycling programs to close the loop.

📎 Related: 5 DIY Projects You Can Create Using Our Recycled Plastic Sheets

✅ Talk to us about custom products

Every recycled plastic product we make is proof that waste can become value.

Whether you’re designing a café, building public furniture, or landscaping a community garden and choosing recycled plastic means:

- Supporting circular manufacturing

- Reducing plastic waste

- Creating impact that lasts

📌 Return to: How Recycled Plastic Products Drive the Circular Economy in Australia