In a world rapidly shifting toward sustainability, every product we create should have a purpose and a plan for its entire lifespan. At Resourceful Living, our recycled plastic panels embody this ethos. They’re designed with circularity in mind, meaning they serve their purpose again and again with no waste left behind.

📌 Related: How Recycled Plastic Products Drive the Circular Economy in Australia

✅ Shop durable, circular recycled plastic panels

Stage 1: Waste Collection – The Beginning of the Cycle

Every recycled plastic panel starts its journey as discarded waste, think milk bottles, food containers, or shampoo bottles.

We work with:

- Local councils

- Ocean cleanup initiatives

- Commercial recycling centres

The materials are sorted, cleaned, and prepped for transformation.

📎 Related: What Happens to Recycled Plastic? Behind the Scenes of Our Process

✅ Learn how your council can supply plastic

Stage 2: Manufacturing: Giving Waste New Purpose

After shredding and cleaning, plastic is compressed into flat, durable sheets using our in-house moulding system.

- Heated under pressure to form panels

- Cooled slowly to retain strength

- Trimmed, inspected, and finished

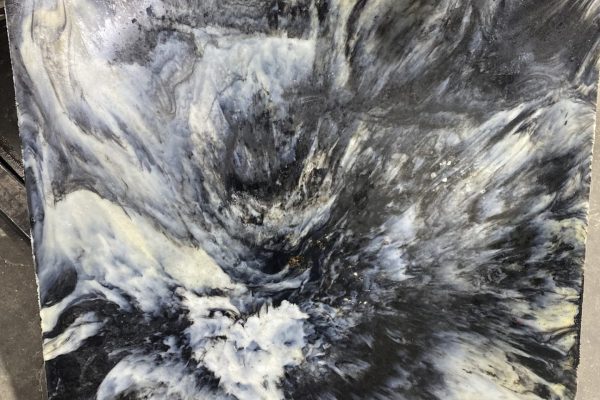

Panels can be customised in:

- Thickness (10mm–50mm)

- Colours and fleck styles

- Size and texture

📎 Deep dive: From Waste to Worth: Transforming Ocean Plastic into Durable Products

✅ Contact Us to Download panel specifications

Stage 3: Use Phase: Real-World Applications

Our panels are designed for long-term use in:

- Construction (cladding, partitions, signage)

- Landscaping (edging, boardwalks, garden beds)

- Furniture (benches, tables, seating)

- Commercial fit-outs (retail, hospitality, offices)

📎 Case studies: Recycled Plastic in Commercial Fit-Outs: Real-World Case Studies

✅ Browse commercial panel applications

Stage 4: Longevity & Maintenance-Free Performance

Unlike timber, metal, or MDF, our panels:

- Don’t warp, crack, or splinter

- Resist UV, moisture, termites, and mould

- Require zero painting or sealing

This means they last 20–50+ years with minimal environmental impact over their use phase.

📎 Related: Outdoor Furniture Made From 100% Recycled Plastic: Is It Durable?

✅ See warranty and longevity data

Stage 5: Reuse, Repurpose & Return

At end-of-life, panels can be:

- Recut and reused in new builds

- Donated or resold for secondary applications

- Returned to Resourceful Living for recycling into new panels

This loop ensures zero waste — panels that don’t end in landfill, but re-enter the system.

📎 Related: Plastic Pollution in Australia: How the Building Industry Can Help

✅ Join our panel return program

Environmental Impact Across the Lifecycle

Each panel saves:

- 1300 plastic containers from landfill

- Carbon emissions from virgin plastic production

- Resources used in timber or metal manufacturing

They’re also VOC-free, non-toxic, and recyclable up to 7 times without quality loss.

📎 Related: Green Star & NABERS: How Recycled Materials Help You Meet Compliance

✅ Request lifecycle data sheets

Why Designers & Builders Trust the Lifecycle

Professionals across Australia choose our panels because they:

- Align with sustainable architecture principles

- Help meet compliance targets and ESG goals

- Reduce long-term material costs

- Tell a visible sustainability story

📎 Related: Why Designers Love Working with Recycled Plastic Panels

✅ Book a materials consult for your project

Full Circle: Closing the Loop

Every Resourceful Living panel comes with a commitment: no waste.

Our manufacturing model is:

- Fully circular

- Australian made

- Transparent and traceable

By choosing recycled plastic panels, you’re not just buying a product — you’re investing in a system that keeps plastic out of nature and in productive use.

📌 Return to: How Recycled Plastic Products Drive the Circular Economy in Australia