Ever wondered what actually happens after you toss a plastic milk bottle into a recycling bin? While many assume it ends up in landfill, the truth is that plastic could become a bench, wall panel, or garden bed.

At Resourceful Living, we’ve built our entire operation around a simple but powerful idea: turning waste into worth. And it starts with a process designed for sustainability at every step.

In this guide, we take you behind the scenes of how recycled plastic becomes a durable, long-lasting material that supports Australia’s circular economy.

📌 Related: How Recycled Plastic Products Drive the Circular Economy in Australia

✅ Explore 100% recycled plastic panels

Why Recycling Plastic Matters

Australia generates over 2.5 million tonnes of plastic waste annually but less than 13% of that is recycled locally.

By recycling plastic:

- We reduce reliance on virgin plastic

- Divert waste from landfills and oceans

- Reduce carbon emissions and energy use

- Create durable, low-maintenance building materials

📎 Related: Plastic Pollution in Australia: How the Building Industry Can Help

✅ See sustainable building products

Step 1: Collection of Post-Consumer Plastic

We work with local councils, businesses, and community groups to source post-consumer plastics such as:

- HDPE (milk bottles, detergent bottles)

- Ocean plastic waste

- Food containers and packaging

The plastic is sorted by type, colour, and quality to ensure consistent results.

📎 Related: From Waste to Worth: Transforming Ocean Plastic into Durable Products

✅ Contact us for supply partnerships

Step 2: Cleaning and Preparation

Collected plastic is thoroughly cleaned to remove:

- Labels and adhesives

- Residue from contents (milk, food, soap)

- Dirt, salt, and other contaminants

Clean plastic is then shredded into flakes the raw material for our next step.

This phase ensures the panels we produce are not only high-performing but also safe and consistent for use in homes, schools, and commercial spaces.

Step 3: Melting and Compression Moulding

Plastic flakes are fed into our custom moulding equipment, where they’re:

- Heated to a specific temperature

- Compressed into flat sheets using moulds

- Cooled gradually to retain strength and structure

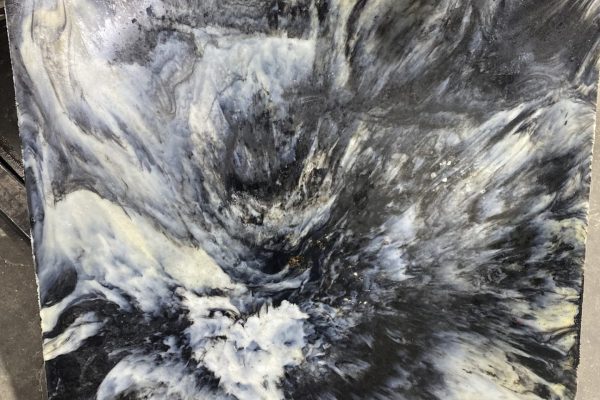

Depending on the application, we adjust thickness, colour, and surface texture.

Panels range from:

- 10mm to 50mm thick

- Smooth or speckled finishes

- Custom sizes and colours on request

✅ Browse recycled plastic range

Step 4: Cutting, Finishing & Quality Checks

Once moulded, sheets are:

- Trimmed to standard or custom dimensions

- Sanded and checked for any surface imperfections

- Strength-tested for commercial use

We also offer:

- Routing and engraving

- Pre-drilled options for installers

Every panel is tracked back to its original waste stream to ensure full transparency.

📌 Related: The Lifecycle of a Recycled Plastic Panel

Step 5: Distribution to Builders, Designers & Councils

Once complete, our panels are:

- Delivered to trade clients across Australia

- Used in commercial fit-outs, outdoor spaces, landscaping, and more

- Installed by builders, designers, and homeowners

Every panel contributes to a circular economy by replacing virgin materials and reducing waste.

📎 Case studies: Recycled Plastic in Commercial Fit-Outs: Real-World Case Studies

✅ Get a quote for your next project

What Makes Our Panels Different?

- ♻️ 100% Australian post-consumer waste

- 🔁 Fully recyclable again at end of life

- 💧 Waterproof, UV-stable, non-toxic

- 🛠 Easy to cut, shape, and install

- 🎨 Available in bold modern colours and custom textures

Compared to timber or MDF:

- No rotting or warping

- No sealing or repainting

- Longer lifespan and lower cost over time

📎 Related: Outdoor Furniture Made From 100% Recycled Plastic: Is It Durable?

Transparency in Manufacturing

We believe in full transparency. Our factory in regional NSW is:

- Powered by renewable energy

- Staffed by local talent

- Committed to zero waste goals

We provide:

- Lifecycle data for all products

- Certificates for recycled content

- Support for Green Star & NABERS projects

📎 Related: Government Incentives for Using Recycled Materials in Construction

✅ Contact Us for technical datasheets

Our recycled plastic manufacturing process is designed to:

- Reduce plastic pollution

- Provide sustainable building materials

- Create real, measurable impact

By choosing our panels, you’re choosing:

- A cleaner environment

- Smarter construction

- Circular thinking

📌 Return to: How Recycled Plastic Products Drive the Circular Economy in Australia