Plastic pollution in Australia isn’t just an environmental issue, it’s an opportunity for the building industry to lead the transition to a more sustainable future.

With construction materials being a major source of landfill and environmental impact, integrating recycled plastic products into building and infrastructure projects can help drastically reduce plastic waste.

This article explores how builders, architects, councils, and developers can actively reduce plastic pollution through material choices and construction practices.

📌 Related: How Recycled Plastic Products Drive the Circular Economy in Australia

✅ Browse eco-friendly recycled plastic panels

The State of Plastic Pollution in Australia

Each year, Australians use more than 3.5 million tonnes of plastic and over 80% of it ends up in landfill or the environment.

Key facts:

- Less than 13% of plastic is recycled locally

- Soft plastics and mixed materials are especially hard to process

- Illegal dumping and construction waste contribute heavily to land and marine pollution

Common pollution sources in construction:

- Plastic packaging and wrapping

- Offcuts of PVC, insulation, and pipes

- Disposable tools and fasteners

- Virgin plastic products with short lifespans

How the Building Industry Contributes and Can Reduce

The construction sector is one of the biggest generators of waste. But it also holds massive potential to become a leader in material innovation.

Ways to reduce plastic pollution in construction:

- Source materials made from recycled plastic

- Design for longevity and modular reuse

- Minimise single-use plastic on site

- Choose materials that are recyclable at end-of-life

📎 Related: The Lifecycle of a Recycled Plastic Panel

✅ Get specs for recyclable materials

Introducing Recycled Plastic Panels for Construction

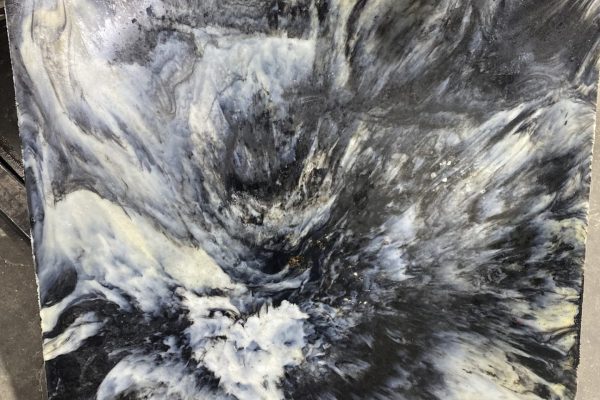

At Resourceful Living, we manufacture high-performance panels from 100% post-consumer plastic.

Key benefits:

- Replace timber, MDF, metal, or PVC

- Waterproof, UV-stable, and termite-proof

- No painting or sealing required

- Fully recyclable again at end of life

Common uses:

- Cladding, partitions, and privacy screens

- Raised beds, retaining walls, fencing

- Outdoor furniture and park infrastructure

📎 Related: From Waste to Worth: Transforming Plastic into Durable Products

✅ See recycled panel use cases

Aligning with ESG, Green Star & NABERS

Using recycled plastic products helps projects:

- Meet Environment, Social, Governance (ESG) goals

- Qualify for Green Star and NABERS credits

- Improve compliance with state and local sustainable procurement policies

📎 Related: Government Incentives for Using Recycled Materials in Construction

Why Builders Should Act Now

Choosing recycled plastic panels isn’t just a feel-good move it’s a smart, future-proof material decision that:

- Lowers costs over time

- Reduces maintenance and replacements

- Differentiates your firm in the market

📎 Related: Why Designers Love Working with Recycled Plastic Panels

Your Role in Ending Plastic Pollution

Every construction project is an opportunity to:

- Use recycled materials

- Educate teams and clients

- Build more responsibly

With recycled plastic panels, you make a clear commitment to:

- Reducing landfill and ocean-bound waste

- Supporting local recycling industries

- Creating durable infrastructure that lasts decades

📌 Return to: How Recycled Plastic Products Drive the Circular Economy in Australia