Recycled Plastic Panels & Sheets

Every panel tells a story — a story of sustainability, innovation, and craftsmanship. Our recycled plastic panels are made from 100% post-consumer and post-industrial waste, giving discarded plastics a second life in commercial, architectural, and creative design projects.

- Supporting a Circular Economy

- End to End Process

- 100% Australian Manufacturing

- 100% Australian Waste Plastic

Crafted from 100% Recycled Australian Plastic

All our panels are proudly made in Australia, using plastic waste collected and processed locally. By choosing our sheets, you’re supporting a circular economy and helping reduce landfill waste and the demand for virgin materials.

We use a diverse mix of pre- and post-consumer plastics and transform them through our proprietary manufacturing process into solid, durable, and visually unique recycled plastic sheets.

Each panel can be recycled up to 11 times, extending the lifecycle of plastic and minimising environmental impact.

✅ Made from 100% recycled Australian plastic

✅ Fully recyclable at the end of life

✅ No veneers, no coatings — solid block throughout

✅ Heat resistant – protects from hot pots and pans

✅ Waterproof, weatherproof & lightweight

✅ Shock, impact & chip resistant

✅ Rust-proof, termite-proof & bacteria resistant

✅ Doesn’t react to cleaning chemicals

✅ Low maintenance, easy to clean

✅ Customisable sizing and thickness

In-House Cutting & Finishing Services

We offer a full suite of custom cutting and finishing services to meet your specific needs, including:

Precision cutting to custom dimensions

Edge polishing and rounding

Sanding and surface preparation

Hole drilling and routing

One-off commissions and prototyping

Batch production for commercial orders

From semi-finished parts to fully completed plastic products, our team can bring your ideas to life with minimal waste and maximum impact.

Designed for Commercial, Creative & Sustainable Projects

Our panels are handcrafted at our Newcastle facility by a team of skilled local makers. Every sheet is uniquely pressed and visually distinct — no two panels are ever exactly alike.

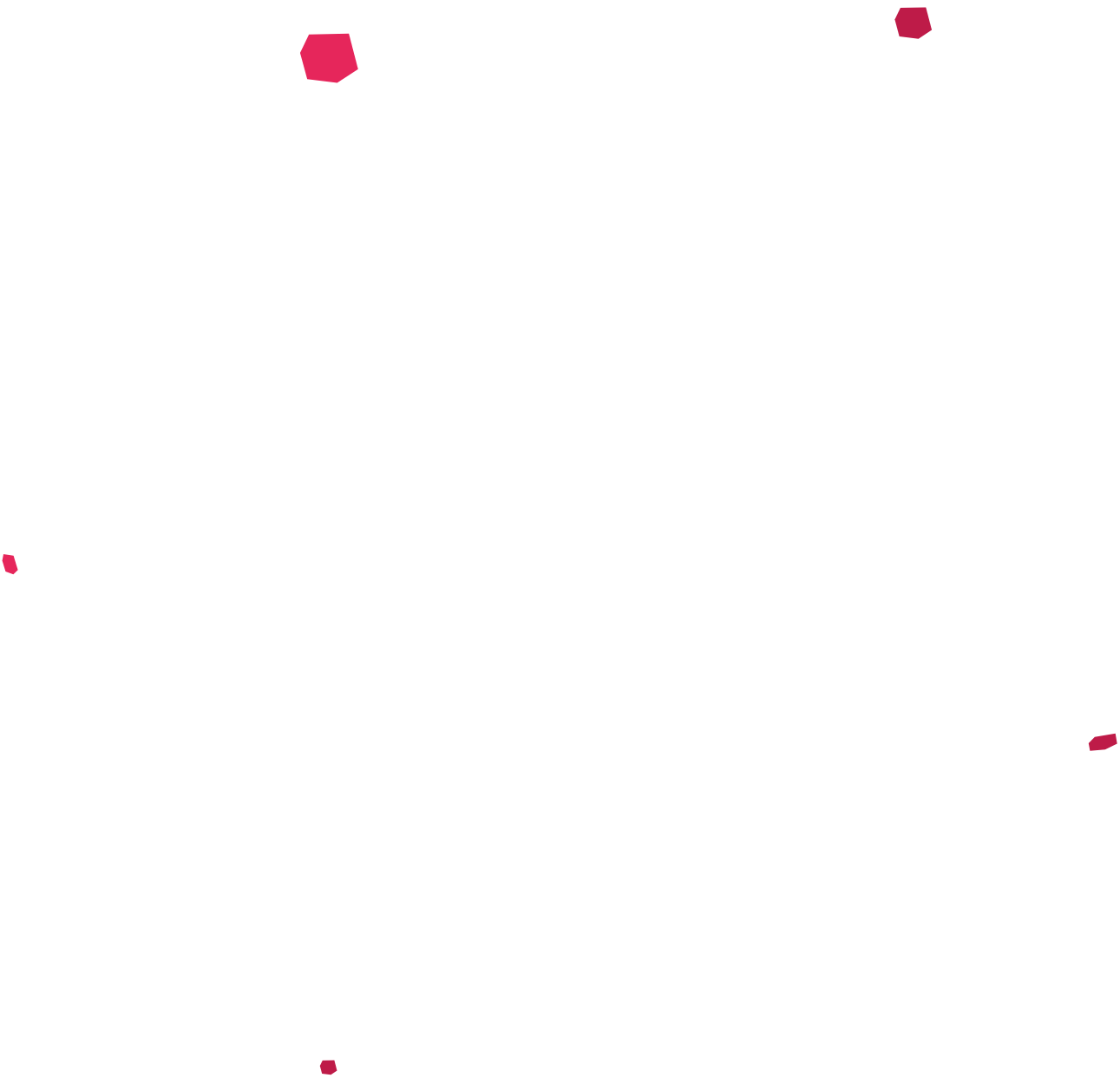

Whether you’re working on a bold commercial fitout, retail design, benchtop installation, or architectural feature wall, our recycled plastic sheets are built to combine durability with design impact.

Standard Sizes & Thickness Options

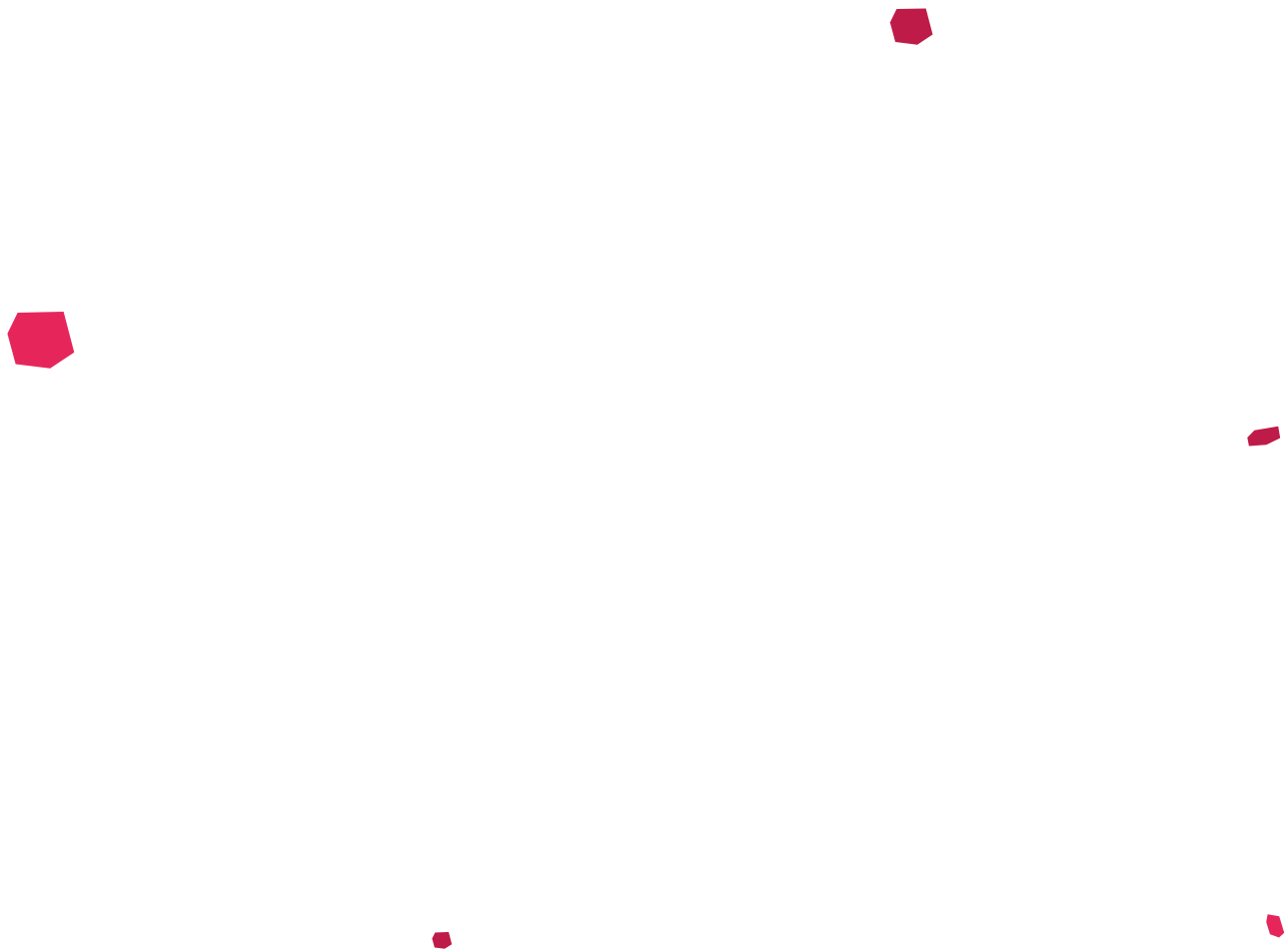

We manufacture plastic panels in a standard size of 2400mm x 1200mm, with thicknesses of:

6mm

12mm

20mm

40mm

Need a custom size or thickness? We’re here to help. We regularly collaborate with clients on tailored sheet sizes and bespoke manufacturing to suit project-specific requirements.

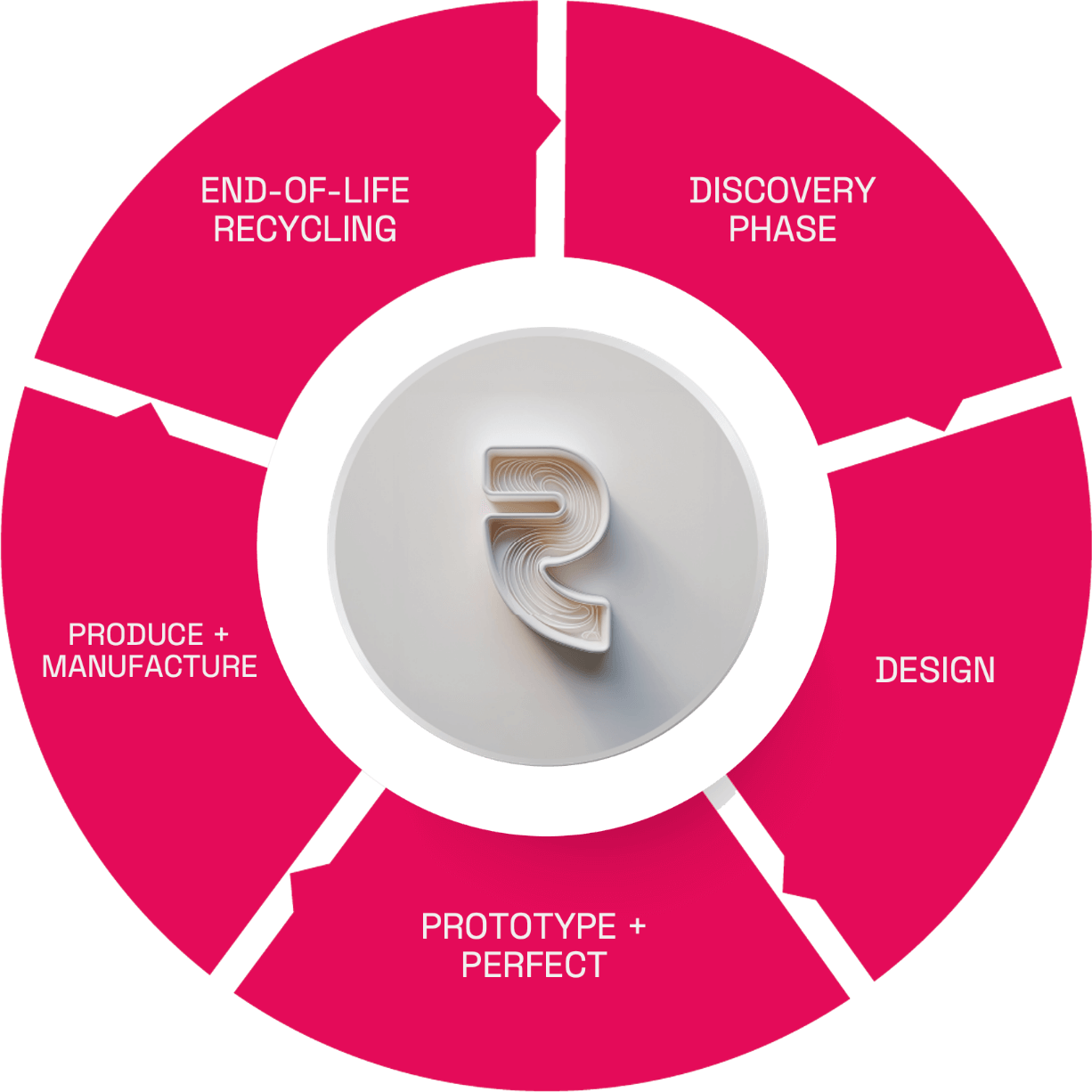

Our Process: Circular, Sustainable, Reliable

We’ve developed a proprietary manufacturing process that ensures every panel meets high standards of performance, finish, and sustainability. Our process allows us to work with clients to create bespoke materials from unique colour blends to specific density or strength requirements.

Our Bespoke Design Process:

- We learn about your requirements, quantities, shape, sizes and how you want to be part of Resourceful Living

- Engage with key stakeholders within your organisation including engineers, architects, designers, managers, and end users.

- Utilise video conferencing to facilitate communication and showcase material examples.

- Emphasise a hands-on approach by involving stakeholders in the journey and process.

- Assess current systems and workflows to identify opportunities for integration and improvement.

- Gather initial feedback and insights to tailor solutions that align with your organisational goals and sustainability objectives.

- CAD drawings, detail needed and design include specific coloured sheets.

- Identify and produce designs tailored to your specifications, requirements, and inspiration.

- Collaborate with key stakeholders to manage the applications, limitations, and advantages of recycled plastic.

- Review design stages from draft to final version.

- Provide 2D and 3D CAD drawings for detailed visualisation.

- Integrate feedback and make adjustments to refine the design and optimise performance.

- Testing, colour, strength, food grade, manufacturing a real life model.

- Transform designs into physical prototypes using recycled plastic.

- Improve and tweak prototypes to ensure they fit real-world applications effectively.

- Refine designs to reduce weight and cost while preserving functionality.

- Test prototypes to assess performance and durability in real-world conditions.

- Iterate on design based on feedback and testing results to optimise the final product.

- Jump straight from 1 to 4 or 2 – 4. Provide CAD drawings and we can cut and do. All machinery under one roof and can do in house without adding subcontractor costs.

- Scale up to full production using our advanced manufacturing processes.

- Utilise precision compression moulding and 3D printing to ensure consistency and quality.

- Implement quality control measures to maintain high standards throughout production.

- Optimise production workflows to enhance efficiency and reduce lead times.

- Manage supply chain logistics to ensure timely delivery of materials and finished products.

- Ensure that all products manufactured are fully recyclable at the end of their lifecycle.

- Facilitate the return of used products to Resourceful Living for proper recycling and repurposing.

- Offer customers solutions for managing and offloading their waste efficiently.

- Promote a circular economy by closing the loop and reintroducing recycled materials into new products.

- Provide guidance and support for customers to ensure their waste aligns with sustainable disposal practices.

Track and report on the environmental impact and recycling rates of products to continuously improve sustainability efforts.

Driving the Circular Economy — One Panel at a Time

Our work isn’t just about making recycled plastic sheets — it’s about creating a sustainable system. Every panel we produce helps solve the global plastic waste problem by:

Diverting plastic from landfill and waterways

Reducing demand for virgin plastic production

Supporting Australian jobs in recycling and manufacturing

Enabling sustainable design in architecture and construction

Educating and inspiring industries to build with circular materials

By choosing our panels, you’re making a material choice that matters — environmentally and economically.

Where Can You Use Recycled Plastic Panels?

- Office and retail fitouts

- Hospitality interiors and signage

- Commercial benchtops and counters

- Outdoor furniture and cladding

- Feature walls and partitions

- Sustainable product prototyping

- Joinery and cabinetry applications

- Custom art, architecture, and installation design

Why Buy Recycled Plastic Sheets From Us?

We’re more than a supplier — we’re a partner in sustainable design. When you work with us, you’re not just buying a product. You’re joining a growing movement toward conscious construction and circular manufacturing.

Our panels help you meet green building standards, earn sustainability credits, and bring your clients an authentic eco story they can feel proud of.

Ready to Order? Let’s Talk

Looking for recycled plastic panels that combine performance, style, and sustainability?

We’d love to collaborate with you. Whether you need a single custom panel, a large order for a national fitout, or a bespoke finish that’s never been done before — we’re here to help.

Contact us today to get a quote, request samples, or discuss your next project.